It’s easy to take mobility for granted until it’s taken away. For millions of people living with physical disabilities, access to functional, reliable assistive technology isn’t just important, it’s life-changing. But when that technology fails or doesn’t exist yet, what do you do?

If you’re Thomas Quiter or Devin Hamilton, you don’t wait around. You engineer your way through the problem.

Hurdles to Independence

Quiter, founder and president of the Mobility Independence Foundation, has made it his mission to change how we think about and build durable medical equipment (DME). “The Foundation seeks to not only reverse engineer durable medical equipment,” he explains, “but also create new open-source designs for DME so that anybody of means can build what they need, whether it is customized, modular, or whatever they need for their particular disability.”

Quiter speaks from experience: He was once stuck in his apartment for five years because he didn’t have access to an adequate wheelchair. “That was in 2014,” he says, “and here it is 2025, eleven years later, and I have access to just about as many wheelchairs as I’d like. We should all have that kind of access.”

However, for most people, access to functional and durable DME remains a significant barrier. “Today’s power chairs and manual chairs break down at the rate of 50% every six months. The average turnaround time for repairs is five months, while you wait for your chair to be repaired. You lose independence, you lose freedom. But it doesn’t have to be that way.”

Lived Experience for Creative Problem Solving

Devin Hamilton, president of RapAdapt and lead contract mechanical engineer for the Mobility Independence Foundation, doesn’t just build assistive devices, he lives them.

“Living with disabilities can involve lots of problems and obstacles, and an occasional mess. To overcome some of these obstacles, I have been using assistive technology from a very early age. I have used everything from head sticks for mixing cake batter to custom sleds for playing in the snow.”

Devin Hamilton, president of RapAdapt who has cerebral palsy.

Hamilton grew up on a dairy farm in Upstate New York. He and his father rigged up modified farm equipment and designed hitch-and-plow systems for his power chair. Now Hamilton leverages that experience, along with his mechanical engineering degree from the Rochester Institute of Technology, into every project.

As he puts it, “I believe with the appropriate perspective any problem can be a spark for creativity.”

Custom Engineering for Real-Life Needs

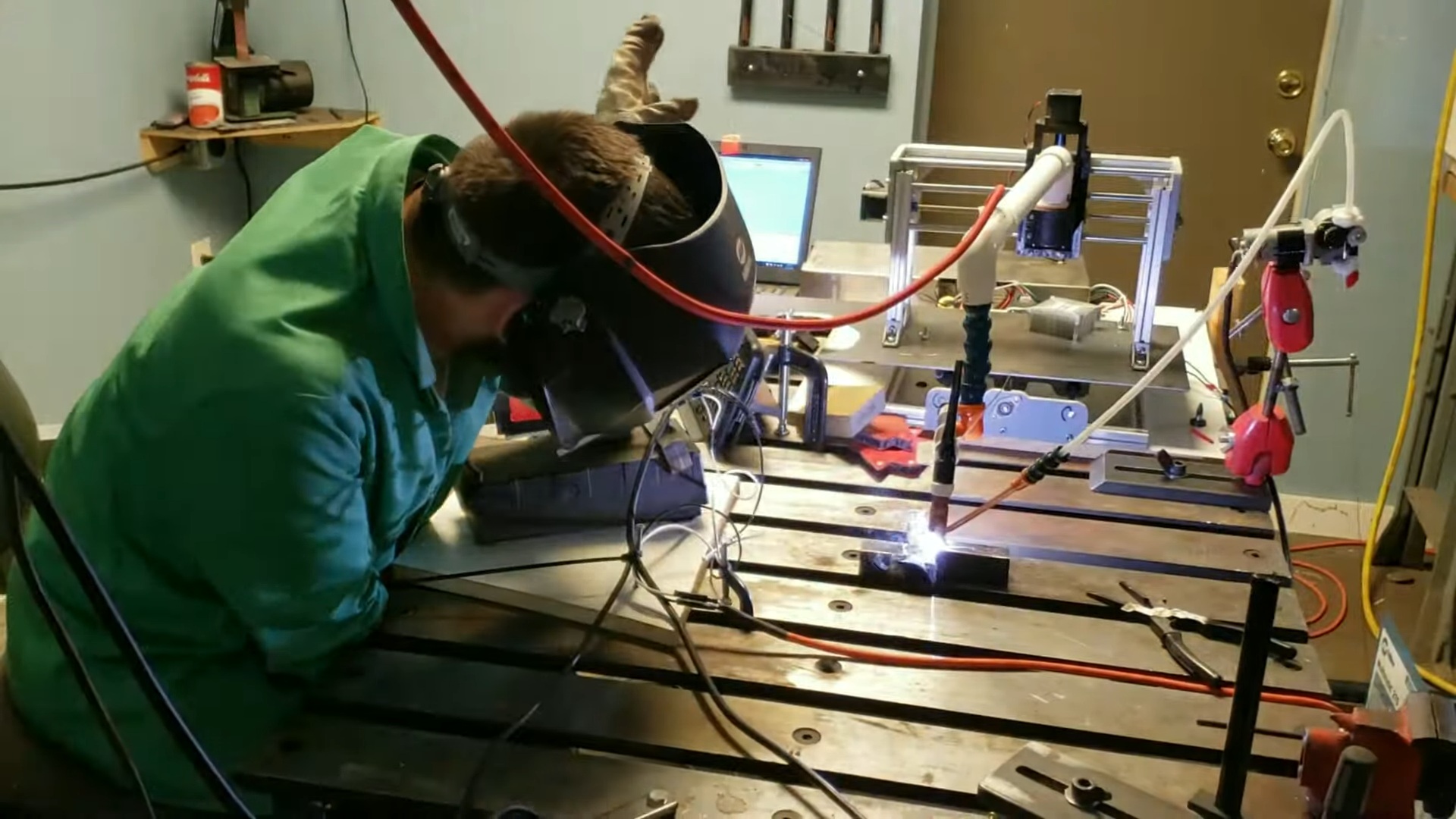

At RapAdapt, every design begins with a conversation. “Our general process involves meeting with the customer and assessing their goals and limitations,” Hamilton explains. “Once we do this, we begin prototyping a custom solution for that individual. Prototyping can involve CAD work, 3D printing, CNC machining, and sometimes welding.”

While the RapAdapt team has access to advanced technologies, such as robotic welding, they don’t let the tools drive the outcome. “Sometimes the most effective solution is the simplest one,” says Hamilton.

This is engineering with empathy. “We understand, on a deeper level than just about anyone in the engineering world, how important independence is in every aspect of life,” explains the RapAdapt website. “We visit our clients in their homes, offices, community centers, remotely, or anywhere in the community that independence matters most.”

A New Standard for Mobility Design

Thanks to this collaboration with RapAdapt, the Mobility Independence Foundation is rewriting the rulebook on mobility device design. “With an open-source design,” Quiter says, “anybody that can turn a wrench and decipher a diagram can help you build it. We have people with disabilities who are those experts.”

Dassault Systèmes SOLIDWORKS® has been essential to the Mobility Independence Foundation’s progress. “Devin Hamilton of RapAdapt is our lead mechanical engineer. He uses SOLIDWORKS to reverse engineer and create new parts where necessary. Without SOLIDWORKS and RapAdapt, we wouldn’t be doing any of this.”

And it’s not just about technical skill, it’s about perspective. “Devin brought a unique perspective by using SOLIDWORKS through the lens of disability, helping us improve a design that was already great, and now, it’s going to be even better,” Quiter says.

Building a Movement

This is bigger than a chair, a device, or a prototype. It’s about dignity, access, and a vision of engineering that serves real human needs.

“We all have value, and we should be adding it back into society, like Devin does. He has cerebral palsy, and he has no trouble using SOLIDWORKS. I think that’s amazing; I think he’s amazing. When we release this model, I hope others will analyze it and identify areas for further improvement. The goal is to encourage continuous evolution to make the design better and better.”

Mobility Independence Foundation Founder Thomas Quiter.

It is exciting to build a future where innovation and accessibility go hand in hand, empowering independence for everyone. You can watch the full video below.

To read the full article, click here.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

Want to learn more and take a deep dive into SOLIDWORKS? Check out our upcoming training classes to enhance your SOLIDWORKS skills. All classes are offered in person and virtually.

SUBMIT YOUR COMMENT