Benefits include faster turnaround times, increased flexibility, reduced costs, and the ability to make strong production parts.

Mark Two – Flagship Continuous Fiber Composite 3D Printer, built to revolutionize your manufacturing operation.

3D Printing Will Revolutionize Manufacturing

3D printing technology has come a long way in recent years and has the potential to revolutionize the way manufacturing companies operate. While traditional manufacturing processes have long been the norm, 3D printing offers several advantages, including faster turnaround times, greater flexibility, and reduced costs. In particular, the Markforged composite 3D printers are powerful tools that can help manufacturing companies take their operations to the next level.

Composite 3D Printing from Markforged

One of the key advantages of the Markforged composite 3D printers is their ability to print with a range of materials, including carbon fiber, Kevlar, and fiberglass. This allows companies to create parts that are not only lighter and stronger than traditional materials, but also more cost-effective. For example, parts made from carbon fiber can be up to 30 times stronger than those made from plastic, and up to five times lighter than those made from steel. This makes the Markforged composite 3D printer an excellent choice for companies looking to create high-performance parts that are both durable and lightweight.

One of the key advantages of the Markforged composite 3D printers is their ability to print with a range of materials, including carbon fiber, Kevlar, and fiberglass. This allows companies to create parts that are not only lighter and stronger than traditional materials, but also more cost-effective. For example, parts made from carbon fiber can be up to 30 times stronger than those made from plastic, and up to five times lighter than those made from steel. This makes the Markforged composite 3D printer an excellent choice for companies looking to create high-performance parts that are both durable and lightweight.

Parts on Demand vs Traditional Manufacturing

Another advantage of Markforged composite 3D printers is their ability to produce parts quickly and efficiently. Traditional manufacturing processes can be slow and require significant setup time, making it difficult for companies to respond quickly to changing market conditions or customer demands. With Markforged composite 3D printers, however, companies can quickly produce parts on demand, without the need for expensive tooling or complex setups. This not only reduces turnaround times, but also enables companies to respond more quickly to changes in the market, giving them a competitive advantage.

Another advantage of Markforged composite 3D printers is their ability to produce parts quickly and efficiently. Traditional manufacturing processes can be slow and require significant setup time, making it difficult for companies to respond quickly to changing market conditions or customer demands. With Markforged composite 3D printers, however, companies can quickly produce parts on demand, without the need for expensive tooling or complex setups. This not only reduces turnaround times, but also enables companies to respond more quickly to changes in the market, giving them a competitive advantage.

Markforged composite 3D printers are also highly versatile, allowing companies to create a wide range of parts and prototypes. This is particularly useful for companies that need to test and iterate on designs quickly, without the need for expensive molds or tooling. With the Markforged composite 3D printer, companies can rapidly create prototypes and test them in real-world conditions, allowing them to quickly identify any issues or areas for improvement. This can help companies to refine their designs more quickly, ultimately leading to better products and a stronger competitive advantage.

3D Printing Accuracy with Markforged

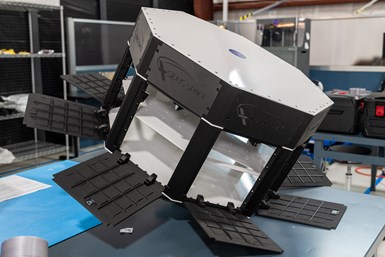

X7 – The turnkey industrial carbon fiber 3D printer for many types of functional parts.

In addition to these advantages, Markforged composite 3D printers are highly accurate and precise. This is important for manufacturing companies that need to produce parts to tight tolerances or require highly detailed or complex parts. With Markforged composite 3D printers, companies can produce parts with a high degree of precision, ensuring that each part meets their exact specifications. This is particularly useful for companies that operate in highly regulated industries, where even small deviations from specifications can have serious consequences.

Cost Effective

Finally, Markforged composite 3D printers are highly cost-effective. While the upfront cost of the printer may seem high, it is important to consider the long-term savings that can be achieved through its use. By reducing the need for expensive tooling and molds, and by enabling companies to produce parts more quickly and efficiently, a Markforged composite 3D printer can help to significantly reduce manufacturing costs over time. This makes it an excellent investment for any manufacturing company looking to improve their bottom line.

Benefits for Composite 3D Printing with Markforged

In conclusion, Markforged composite 3D printers are an excellent choice for manufacturing companies looking to take their operations to the next level. With its ability to produce high-performance, lightweight parts quickly and efficiently, its versatility in creating a wide range of parts and prototypes, and its high accuracy and precision, a Markforged composite 3D printer is an invaluable tool for any manufacturing company looking to improve their competitive advantage. So if you’re looking to stay ahead of the curve and take your manufacturing operations to the next level, a Markforged composite 3D printer is an investment you won’t regret.

Learn More about Markforged 3D Printers.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

SUBMIT YOUR COMMENT