Speed is crucial when it comes to competitive cycling. And even if you’re racing on an indoor track with controlled conditions, you’re going to be battling wind resistance and drag every turn of the pedals. With up to 90% of a cyclist’s energy output being spent to overcome air resistance, reducing drag is paramount. Tens of thousands of dollars or more could be spent on an aerodynamic bike. With the rider’s body being responsible for roughly 80% of the drag, and their bike the remaining 20%, it makes far more sense to focus on the rider, the biomechanics in various riding positions, training, and especially, the clothing.

Click here for the full video.

Vorteq is making use of a full-sized, sports-dedicated wind tunnel, a custom fabric wind tunnel, and the latest in 3D scanning technology to create custom skinsuits for cyclists. A skinsuit is essentially the most aerodynamic piece of clothing a rider can wear, reducing their level of drag down below that of being naked. A quality skinsuit should also be comfortable, lightweight, breathable, and made specifically for the athlete wearing it. Otherwise they’re bound to fit improperly and wrinkle up, and in the world of aerodynamics, every wrinkle adds to performance-killing drag. As well, many fabrics “open up” when overstretched, introducing greater drag across their surfaces, so fabrics and seams should be chosen carefully for specific areas of the body, with each skinsuit designed and manufactured to have the exact amount of fabric tension for that particular rider’s anatomy, to achieve optimum airflow and the least wind resistance. Considering how body shapes and sizes of cyclists can differ so dramatically, such a customized fit simply isn’t possible with an off-the-shelf, small-medium-large type of skinsuit.

Vorteq’s parent company, TotalSim, has deep experience from working closely with professional cyclists, Olympic cycling teams, Tour de France riders, and other top cyclists over the past 10 years. This has made it possible for Vorteq to create what they believe to be the fastest skinsuits available today. To engineer their skinsuits beyond what was ever possible in the past, Vorteq has invested in excess of $500,000 in R&D, while testing more than 45,000 different material, tension, and speed combinations in the specialized wind tunnels at Silverstone Sports Engineering Hub (SSEH). The end result is every athlete receives their own skinsuit, created with custom patterns and fabrics, each designed for maximum performance.

Despite Vorteq’s lengthy work exclusively with Olympic teams and other elite athletes, as of January 1st, 2020, their custom skinsuits are available to serious riders of all levels of experience. This means that any cyclist, not just the pros, now has the chance to get a custom Vorteq skinsuit, and when they’re sprinting towards the finish line, they’ll be wearing the same level of skinsuit technology as if they were one of Vorteq’s Olympic clients.

To create these custom skinsuits, the use of a 3D scanner is a crucial element for digitally capturing a rider’s exact anatomy, and in the hours that follow those few minutes of scanning, all the sizes, patterns, and types of fabric will be meticulously selected in the computational draping system and then assembled by Vorteq’s skinsuit team.

In the past, TotalSim was using an arm-based scanner for scanning race cars, bicycles, and other objects, but when it came to using the scanner for capturing people, they ran into significant difficulties and weren’t able to proceed any further with their old technology.

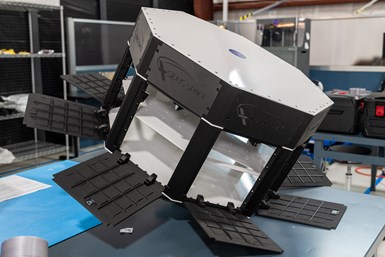

That’s when Vorteq turned to Artec Ambassador Central Scanning, specialists in all aspects of 3D scanning. During an onsite visit and consultation, the experts at Central Scanning recommended the Artec Leo, a revolutionary handheld 3D scanner with a built-in touchscreen and up to 80 fps capture rate, as well as being an entirely cable-free scanner that excels at capturing medium-sized objects such as people in mere minutes. TotalSim had used two Artec scanners in the past for their CFD and metrology work, Artec Eva and Artec Spider, so they were already familiar with Artec’s high level of scanning technology.

“When we’re making our skinsuits, we’re working directly from the Leo scans, so it’s not measurements we’re taking, it’s the exact physical data that’s being used, and the difference is crucial. Because if you’re taking physical measurements and then entering them into a CAD system, or a computational draping system like ours, something is going to be lost in the transition. And that something can easily result in imprecise dimensions being used to create a skinsuit, which is entirely unacceptable to us. Even one tiny mismeasurement could result in a wrinkle here or there, or fabric being overstretched. So, for us, how Leo gives us the exact physical data of the athlete to work with makes all the difference.”

Quilter summarized the process, “From the time an athlete walks in the door and we start scanning with Leo, then using Artec Studio to post-process the scans, followed by 3D modeling work in Geomagic Wrap, and finally exporting the 3D model for use in making a skinsuit, we are looking at about 2 hours total, which absolutely wasn’t possible in the past, not even close. And as far as the total production time for a skinsuit that’s ready to race, currently we’re at 2 days, but that gap is narrowing, and we’re shooting for a 24-hour turnaround time, which we’re sure to hit before too long.”

In addition to Vorteq’s skinsuits and TotalSim’s biomechanical consulting and training services, they also provide scanning services to a range of clients, including cycling teams. Their Leo has played a pivotal role in their ability to 3D scan anywhere their projects lead them, whether in-house, around the UK, or overseas.

As Quilter explained, “In contrast to our previous scanners, Leo gives us that flexibility to just pick up and go virtually anywhere in the world to do scanning, without requiring extra hardware, just the Leo itself. This kind of freedom is tremendous when you’re going offsite to random locations that aren’t exactly laboratories in regards to their conditions.”

Click here to read more about this post…

Curious about 3D scanners? Contact an expert from The SolidExperts to learn more.

SUBMIT YOUR COMMENT