When disruptive events hit supply chains prior to the 2020 Coronavirus pandemic, finding a solution was far more simple. It wasn’t the norm to have multiple, global-scale disruptions happening simultaneously —so finding a new supplier for production line replacement parts wasn’t an insurmountable task. So back then, theoretical supply chain ‘resilience’ could be achieved with traditional procurement practices and risk management frameworks.

Today, supply chain disruptions continue to occur in consistently higher frequencies and less-predictable magnitudes. For manufacturers relying on yesterday’s traditional supply chain management strategies, pairing a single disruptive event with the need for even a simple replacement part can easily lead to extended production line downtime.

So, in today’s world of precarious availability, how can manufacturers ensure uptime on their factory floors? While traditional just-in-time (JIT) supply chain management models alone are too taut and brittle to succeed through constant uncertainty, today’s advanced additive manufacturing technologies have evolved to add resilience through greater flexibility.

Through providing production capabilities at the point of need for everything that keeps factory floors running — high-performance replacement parts, production tooling and fixtures, MRO parts, or ergonomic equipment — today’s industrial 3D printers can grant a powerful new autonomy to supply chain operators.

Read this article to learn why today’s unpredictable world requires new ways to build supply chain resilience — and why manufacturers around the world are turning to additive to keep production lines running through a new era defined by uncertainty.

The supply chain status quo: getting parts ‘just-in-time’ – Since the 1970s, the world has placed its trust in JIT manufacturing. Under optimal conditions, this model is efficient, minimizing excess overhead by only producing levels of inventory required to meet customer demand.

As the efficiency of JIT manufacturing brought this philosophy into widespread practice across factories around the globe, most manufacturers have modeled their supply chain management strategies with a JIT approach — meaning they only order materials and other components from upstream suppliers right before they’re needed, while ordering little (if any) more than the precise amount needed at that time.

Prior to 2020, supply chains were more simple to manage. While disruptive events still occurred, they were typically more predictable in scale, easier to contain at these lesser magnitudes. As a result, traditional risk management frameworks were sufficient mitigation.

Today’s supply chain landscape: can you plan for it? While manufacturers historically managed supply chain disruptions through comprehensive risk mitigation plans, theoretical ‘resilience’ of these supply chains has been built on assumptions that their impacts can be consistently planned for and solved.

However, when considering what specific factors and variables ultimately influence and limit availability of large portions of the world’s supply chains — can manufacturers accurately track, predict, and plan around large-scale geopolitical shifts far beyond their control? Factors behind these large-scale disruptions tend to unfold behind the curtain. They’re invisible until the catastrophic impact has already materialized, blindsiding supply chains and knocking them over.

Supply chains are complex, with countless variables and overlapping dependencies. A disruptive event at any single point in these interconnected webs can have unpredictable rippling effects that ultimately lead to the terminal failure of numerous other supply chains.

In the new status quo of uncertainty, the JIT supply chain model has been vulnerable to these disruptions. JIT relies on lean inventories and precise coordination between suppliers and manufacturers. When the impacts of disruptions cascade across entire supplier ecosystems, solutions aren’t as simple as having straightforward contingency plans. Without large stocks of inventory to fall back on — or fast and versatile production available at the point of need — these factory floors are susceptible to extended periods of costly downtime. A single replacement part, which can take months to get, can shut down an entire production line until it’s received.

Building supply chain resilience today: production at the point of need adds greater flexibility Constantly re-evaluating supply networks is not a bulletproof solution. Not only does identifying and integrating new suppliers into existing systems take valuable time and resources; but the higher frequency of disruptive events makes the perpetual re-planning of complex, interconnected manufacturing supply chains unviable as a long-term strategy.

Manufacturers looking for a more reliable buffer against disruptions to factory floor operations therefore need to shift their approaches to supply chains into a more agile and flexible strategy. So what can manufacturers do to acquire crucial replacement parts without jeopardizing production uptime with uncertainty and unnecessarily long lead times?

As federal initiatives like AM Forward highlight the transformational value of cutting-edge technologies like additive manufacturing in supply chain management, growing numbers of organizations have brought industrial 3D printing to their factory floors to bolster operations.

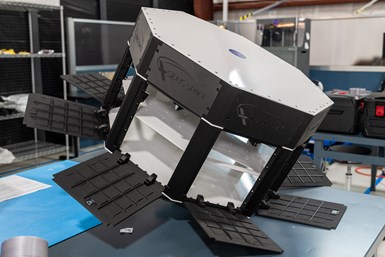

Modern additive manufacturing technology is able to quickly produce production-grade parts in metal-strength composites and a wide variety of industrial metals. When problems arise, technicians can quickly and easily print solutions they need now on factory floors — tooling and fixtures, MRO equipment, ergonomic solutions, or any other critical production components — without prolonged downtime.

3D printing ultimately means you have flexibility in your supply chains without having to double down on physical inventory. Instead of keeping spare parts stocked, parts can be stored in the cloud as digital inventory — which can then be printed into a tangible part in a matter of hours.

With far higher levels of risk and uncertainty a near constant in today’s supply chains, the ability to design and print a solution to any challenge that arises grants factory floors autonomy and control in today’s world of unstable supply chains — rather than waiting weeks or even months for a critical part to arrive.

How additive manufacturing builds supply chain resilience Production at the point of need through industrial 3D printing provides supply chain resilience to manufacturers in several ways:

-

Reduced dependency on traditional suppliers: AM enables manufacturers to produce parts and components in-house, reducing their reliance on external suppliers. If there are disruptions to existing supply chains, staff on the factory floor are empowered to take matters into their own hands by designing and 3D printing a solution.

-

On-demand production: With 3D printing, manufacturers can produce items on-demand, eliminating the need for large inventories and minimizing the risk of excess stock.

-

Digital inventory: This allows parts to be stored in the cloud as 3D design files, which can then be turned into tangible objects in a matter of hours. This flexibility allows manufacturers to respond quickly to changes in demand or unexpected disruptions in the supply chain.

With today’s more sophisticated 3D printing software platforms, large industrial manufacturers like Vestas are using secure digital inventories to store certified, up-to-spec parts that can be easily searched for and printed to wherever they’re needed. A secure, shared repository of up-to-spec part files allows their transfer without risking design inconsistencies or risking an intellectual property leak.

-

Localization of production: 3D printing lets manufacturers establish production facilities closer to customers. This localization reduces transportation costs, lead times, and mitigates the impact of potential disruptions associated with long-distance shipping.

-

Spare parts availability: 3D printing can address the challenge of spare parts availability, especially for older or discontinued parts. Instead of relying on the availability of spare parts from suppliers and working with their timelines, manufacturers can produce the required parts on-demand using 3D printing, reducing any factory floor downtime.

-

Distributed manufacturing networks: 3D printing enables the establishment of distributed manufacturing networks where multiple facilities can collaborate and share production capacities. In the event of a disruption in one location, production can be shifted to other facilities within the network, ensuring continuity and reducing the impact of supply chain disruptions.

To read the full article, click here.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

SUBMIT YOUR COMMENT