Due to developments in additive manufacturing (AM) technology within the last decade, today’s professional 3D printers are used for much more than creative hobbies and rapid prototyping.

Did you know that a 3D printer no larger than a desktop home aquarium can print plastic parts strong enough to be used as functional components on race cars? Today, professional 3D printers are trusted to build parts for many high-risk, safety-critical applications: such as taking flight aboard aircraft and carrying loads up to 960 kg (2116.44 lbs.) in factories. New part strength and other technological improvements in the 3D printing space have opened up many incredible new uses for today’s professional 3D printers. So, what are today’s 3D printers capable of — and what technology enables these new capabilities?

What can you do with a professional 3D printer?

What can you do with a professional 3D printer?

Being able to print strong parts at the point of need — and with the right material properties — opens up a lot of possibilities for how manufacturers can leverage 3D printing:

In the factory. A professional 3D printer can be used to quickly and cheaply build tooling, build components for industrial machinery, or swiftly fabricate replacement parts where needed. Parts built with today’s professional 3D printers have been used to repeatedly lift and move loads of up to 2116.44 lbs. in factory settings.

Aircraft parts. Strong, light, flame-retardant AM materials engineered specifically for demanding aerospace applications are available. Traceability in these AM materials means that aerospace manufacturers can simply hit “print” to build flight-ready end-use parts.

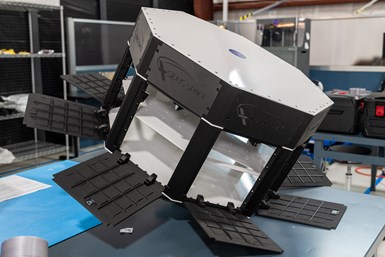

Robotics. AM is ideal for the manufacture and maintenance of robotics systems. A team consisting of 60 engineers from the NASA Jet Propulsion Laboratory (JPL), Massachusetts Institute of Technology (MIT), California Institute of Technology (Caltech), and other organizations used their professional 3D printer in a robotics competition. 3D printing allowed them to build an impact-resistant, lightweight body for their robotic vehicle and perform quick field maintenance for broken parts.

Automotive. Race car teams are using additive manufacturing to quickly build end-use car parts that are strong, lightweight and heat-resistant to maximize performance.

Production parts: Manufacturers might also use 3D printers to fabricate parts with complex geometries, bespoke end-use parts, or for more cost-efficient low-volume production runs. Today’s professional 3D printers can reliably produce high-quality surface finishes, making them suitable for building end-use parts on consumer goods, such as Wilson Benesch turntable systems.

Supply chain control. Having access to in-house AM allows manufacturers to rethink their supply chains with less risk. Lead times can be drastically reduced, dependencies on external suppliers can be eliminated, and potential logistical delays can be circumvented. Engineers won’t have to wait weeks to months for the parts they ordered to arrive. Through the cloud, parts saved as digital inventory can be sent to any printer in the network — and quickly built at the specific point of need in just hours to days.

What powers today’s professional 3D printers? Until the last five years or so, even top-of-the-line professional 3D printers were relegated to rapid prototyping and little else. These six key advancements to AM technology have made 3D printing a suitable means for manufacturing strong, end-use parts at the precise time and point of need:

- Power, speed, size, reliability. To meet manufacturers’ needs for scaled production, professional 3D printers evolved with significantly improved print speeds, reliability, maximum part sizes, and part quality. Even desktop-sized 3D printers can now be trusted to produce consistent, high-quality results in key manufacturing roles.

- User-friendliness. Development of user-friendly 3D printing software has streamlined and automated many previous points of complication in older AM workflows into a far more simple process. Now, effective use of professional 3D printers does not require specialized labor or AM expertise.

- Innovative materials. Today’s 3D printing materials have grown beyond prototyping materials. Vendors have engineered specialized, high-performance 3D printing materials for demanding applications, such as aerospace-grade composites that are stronger than machined aluminum but with just a fraction of the weight. Parts can be printed with high heat resistance, chemical resistance, and fortified with continuous fibers to add extra strength anywhere within the part.

- Metal FFF. Metal fused filament fabrication (FFF) technology means 3D printing metal parts is now faster, safer, and more cost-effective than previously. Metal FFF printers offer a wide range of material availability — such as stainless steel, tool steels, Inconel, and copper — and can be operated with minimal PPE and safety precautions.

- Industry 4.0 Connectivity. Cloud-based connectivity between each user and set of printers also allows for distributed manufacturing operations. Users can initiate prints across 3D printers in different geographic locations. The ability to ensure the right part is available both where and when it is needed can solve many critical supply chain inefficiencies and challenges.

3D printing software integrations allow users to initiate part production through requests in core factory systems — such as a manufacturing execution system (MES), Enterprise resource planning (ERP) or enterprise asset management (EAM) system — or, by scanning the barcode of a physical part that needs to be duplicated.

What makes today’s 3D printed plastics so strong and versatile? Today’s professional 3D printers fabricate high-performance plastic parts through building strong composite materials that incorporate continuous fibers for strength, durability, and material property benefits.

What is a composite material? A composite material is made when two or more materials — each with different properties — are combined without blending or dissolving them together. Typically, materials are chosen for complementary properties and result in a material optimized for specific conditions. Composites consist of a weaker binding material that is reinforced with a strengthening material. The ‘fibers’ of a stronger material are surrounded with a less-strong material that is called the ‘matrix.’ Most manufacturing composites involve a plastic matrix such as nylon, while the reinforcing fibers may be fiberglass or carbon fibers. Composite materials are widely used for their high strength and stiffness, low weight, and enabling design freedom. A composite material can be hundreds of times stronger than either of its constituents. While composite materials can be made without professional 3D printers, traditional modes of making composites can be labor intensive, require significant training and specialized knowledge, and require lots of expensive equipment and machinery.

The role of continuous fibers. In the strongest composites from professional 3D printers, continuous fibers act as the strengthening fiber constituent, to be combined with a plastic matrix. Continuous fibers are long fiber tows that are coated in thermoplastic. They endow a composite part with the directional strength of metal. They have elastic moduli between 16 times and 46 times greater than those of plastics. As opposed to chopped fibers which are suspended in the plastic, continuous fibers run uninterrupted through a part, thus distributing the load across the part’s three-dimensional geometry. They perform best in tension, so it is critically important to print them with loading conditions in mind.

3D printing composites with continuous fibers. 3D printing parts with continuous fiber reinforcement (CFR) works by combining continuous fibers with a plastic matrix. When printing a part with continuous fiber reinforcement, the professional 3D printer uses two nozzles and extrusion systems. The plastic material is extruded through a heated nozzle, while a second nozzle releases continuous fibers into the material. Releasing the plastic material through the heated nozzle thermally fuses the thermoplastic coating that surrounds each continuous fiber tow, melting it so it adheres into the plastic matrix. Parts can be reinforced in many different ways to optimize for different loading conditions. Fibers can be laid in a wide variety of 2D orientations within each layer of the 3D printed part. A user can also dynamically control the amount of fiber in the part by altering the amount of fiber in a layer, as well as designating how many layers are reinforced. This control enables engineers to 3D print parts exactly as strong as needed.

To read the full article, click here.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

SUBMIT YOUR COMMENT