Metal 3D printing is changing how we think about fabricating with metal, and as the technology becomes more and more prevalent on manufacturing floors, it’s important for businesses to gain application-centric intuition about the process. Just as machinists understand which components are best made on a waterjet vs. a 3-axis mill, it is essential to know which parts are a good fit for additive manufacturing and 3D printing applications.

The first step to gaining this intuition is recognizing the fundamental benefits of metal 3D printing. The following advantages are the root of each successful metal 3D printing application.

- Geometric Freedom

- No Tooling

- Automation

5 best applications for metal 3D printing

1. Functional metal prototypes: Because metal 3D printing requires no tooling and very little machine setup, it offers a way to produce metal prototypes with minimal effort. This allows customers to have accurate metal parts in hand in a matter of days, helping evaluate designs more quickly while avoiding expensive tooling rework. Engineers can explore more designs in a shorter period of time, compressing their product development cycle.

Metal 3D printing allows this medical device manufacturer to quickly and inexpensively prototype in stainless steel.

2. End-of-arm tooling: Metal 3D printers can produce conformal end-of-arm tooling much easier and cheaper than traditional methods. 3D printing software automatically generates toolpaths, allowing engineers to skip the CAM process. Additionally, the part complexity of conformal grippers introduces no additional cost, so they can be optimally designed to grip parts securely and precisely.

3. Custom tools: While most tools are mass produced, many situations call for specialized instruments that are manufactured in low volumes. Metal additive manufacturing allows engineers to bypass steep overhead and create custom tools at a low cost per part.

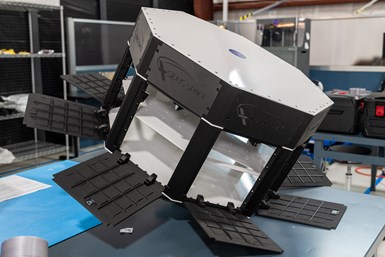

4. Complex bracketry: Metal 3D printing offers an alternative way to create intricate brackets that are difficult or impossible to machine. Thin, complex lattices pose no challenge the 3D printing process, allowing for the inexpensive production of brackets with specialized geometries.

5. Low-volume end-use parts: Metal additive manufacturing can remedy high part costs for low-volume production. 3D printers make parts without tooling, getting rid of the need to spread overhead across thousands of parts.

To read the full article, click here.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

SUBMIT YOUR COMMENT