Re:3D began with a mission to give ordinary people the means to solve their own problems through the extraordinary technology of additive manufacturing. The Texas-based company spun out of Engineers Without Borders and NASA’s Johnson Space Center in 2013. Because Re:3D’s engineering team had witnessed communities worldwide struggling without access to essential tools, they were determined to build solutions that could make a difference.

“At our core, we are a social enterprise, and so we truly believe in the opportunity of giving economic empowerment and independence to people to create things for their own communities or organizations. We do that by making large industrial 3D printers affordable.”

co-founder Samantha Snabes.

Rather than chase venture capital, Re:3D launched with a modest $40,000 grant from Start-Up Chile and a successful $250,000 Kickstarter campaign for their first product called the Gigabot: a human-scale industrial 3D printer that could be sold for a fraction of the cost of traditional 3D printers (Human-scale indicates the printer is large enough to print objects of a size useful for human applications, such as furniture, prosthetics, tools, or even entire parts of machines or structures).

Sustainable Manufacturing

The premise was simple: Put the power of massive 3D printing in the hands of real people solving real problems. With a build volume over 30 times that of a desktop printer and an affordable, sub-$9,000 price tag, the Gigabot enables entrepreneurs, educators, and engineers to create everything from prosthetics to water system parts.

The GigabotX 3D printer, the next evolution in 3D printing technology, can print using virgin polymer pellets or recycled plastic, helping users advance toward a circular economy where materials are reused rather than discarded.

Bootstrapping Big Machine Design

Building large-format, socially impactful additive manufacturing hardware on a shoestring budget requires more than just idealism.

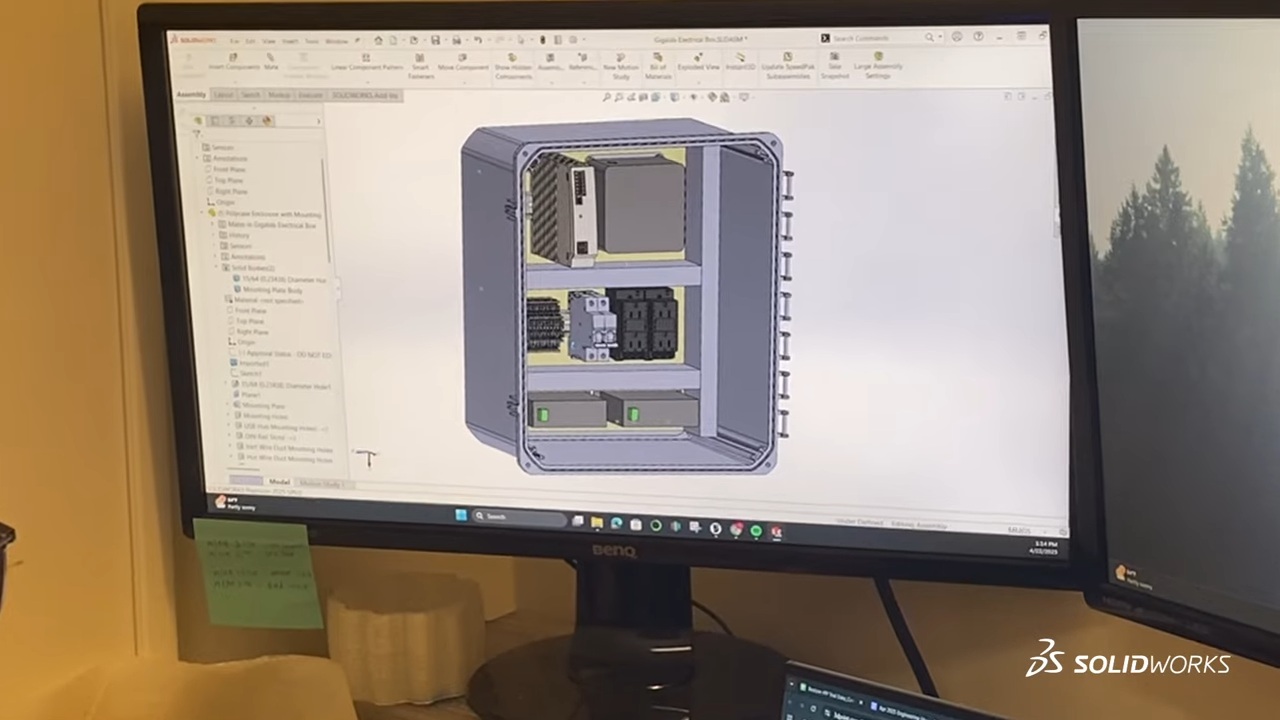

The Re:3D team knew its products had to be durable, modular, and easy to replicate globally. That meant engineering precision was non-negotiable, and that’s where Dassault Systèmes SOLIDWORKS® entered the picture. Re:3D joined the SOLIDWORKS for Startups program after Snabes met a representative from SOLIDWORKS at a startup competition. Access to the top 3D mechanical CAD software proved to be a turning point.

The 3D printing machines from Re:3D are in 60 countries worldwide. Therefore, every machine must be consistently designed and delivered while maintaining the highest standards.

“Having the latest and most advanced tools at our fingertips is critical. We rely heavily on SOLIDWORKS. We could not do it without software tools like SOLIDWORKS.” Samantha Snabes, cofounder.

Mission Matters

Importantly, the relationship with SOLIDWORKS wasn’t just technical. “We only choose vendors that align with our mission,” emphasizes Snabes. “SOLIDWORKS isn’t just software. It’s a community we’re proud to be part of.”

Re:3D continues to bootstrap its way forward, sustaining growth through hardware sales, contract printing, training, and grants. For every 100 Gigabots sold, Re:3D donates one to a person or group who will use it to make a difference. Through it all, their north star remains unchanged: democratize access to additive manufacturing, disrupt the waste stream, and empower local problem-solvers worldwide. Snabes concludes,

“What we’re able to use through the SOLIDWORKS portfolio enables us to dream big—and print huge—together.”

Learn how you can take your next great product idea to market successfully using SOLIDWORKS.

To read the full article, click here.

Click here to learn more, get a quote, or contact an expert at The SolidExperts.

Want to learn more and take a deep dive into SOLIDWORKS? Check out our upcoming training classes to enhance your SOLIDWORKS skills. All classes are offered in person and virtually.

SUBMIT YOUR COMMENT